Pioneer in Industrial Automations Services | Enriched With Quality in Time

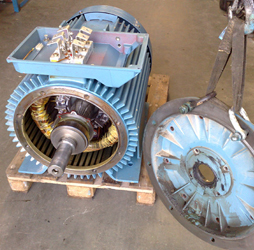

INDUSTRIAL ENGINEERS(INDIA), Only having facility for Rewinding & Re-Pairing of multi Branded A.C/D.C Motors, HT/LT Transformers, Alternators/Generators, Traction motors, Wind mill & turbo Generators, SERVO & Spindle Motors, Re-Winding with Original Specifications, Draw bar & Clamping unit Replacements

It is the aim of INDUSTRIAL ENGINEERS (INDIA) to provide its clients with a Quality Services. To meet customers needs and expectations, a Quality Assurance system, in line with the ISO quality management standard, has been implemented through the use of a management-led control system. A dynamic approach has been developed in order to meet our client's ever-changing needs and requirements.

The Directors of INDUSTRIAL ENGINEERS (INDIA) have the responsibility of ensuring that all staff of the company complies with their instructions regarding Quality Assurance. The documented Quality Assurance system is maintained through the management functions and it is mandatory for all staff to adhere to the agreed procedures and to support the drive for excellence.

The Company employs a management structure which develops authority and responsibility for Quality Assurance, Industrial workplace safety and customer’s satisfaction. There is a dedicated management representative who has responsibility to establish and maintain the documented Quality Assurance and Safety systems and is charged with ensuring its continual improvement.

The management system has established procedures for regular quality audits, which review and report on quality and safety arrangements and recommend action to be taken to prevent Recurrence of a problem, Identifying, where appropriate, any additional resource requirements. A nominated management representative monitors and measures performance against stated objectives and is responsible for ensuring the Company policy is communicated to, and understood by, all staff.

To offer our clients the most efficient Service, Regular reviews of existing standards are undertaken to ensure that the service provided reflects the current expectations of the market.